© 2026

All rights reserved segmag.pt •

Made with♥by

Criativatek

Talk to us!

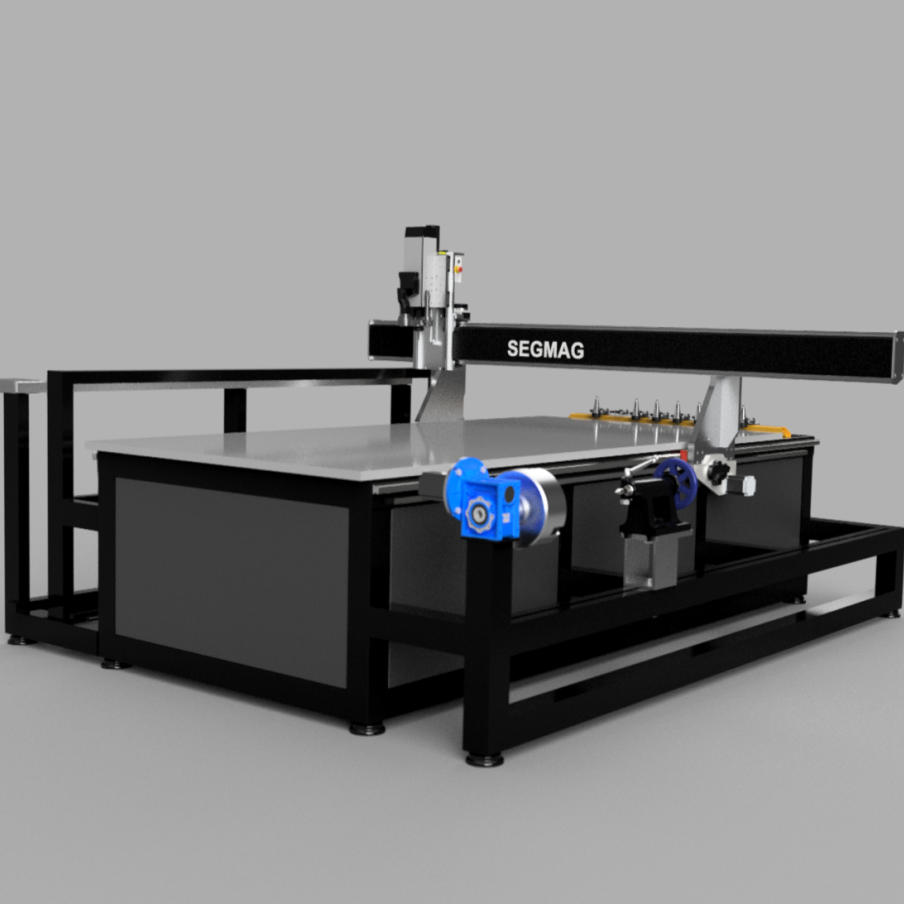

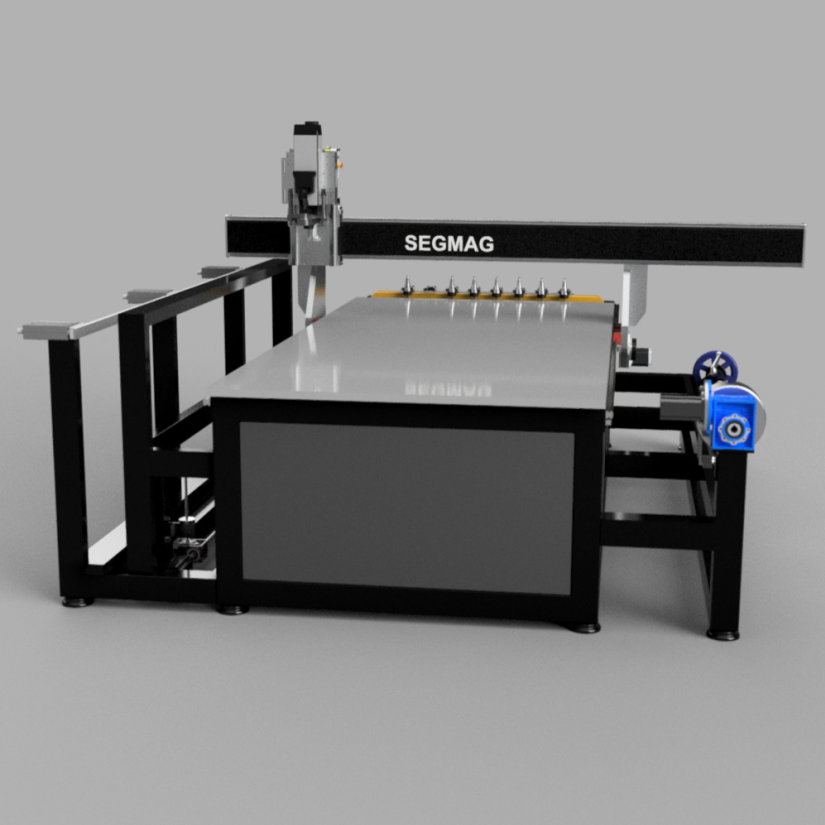

The CNC Alfa Pro is a precise, robust, and configurable industrial solution. With a reinforced structure, automatic dust extraction, and CAD/CAM compatibility, it ensures high productivity and durability. Ideal for those who demand reliable performance in CNC cutting and machining projects

Reinforced structure, professional precision, and maximum adaptability for demanding production environments.

The CNC Alfa Pro represents the natural evolution of performance and engineering in the Segmag CNC machine lineup. Building on the experience gained from the Beta Pro model, the Alfa Pro was developed to offer enhanced robustness, increased precision, and advanced features that meet the demands of professional production environments. It is the ideal choice for those seeking a high-quality CNC machine with variable dimensions, adaptable to different working contexts. It combines cutting-edge technology with an optimized design to streamline daily operations, while remaining true to Segmag’s core principles: ease of use, solid construction, durability, and low maintenance costs.

Compared to the Beta Pro, the Alfa Pro includes significant improvements such as a reinforced structure, larger motors, higher travel speed, and other technical optimizations that boost productivity.

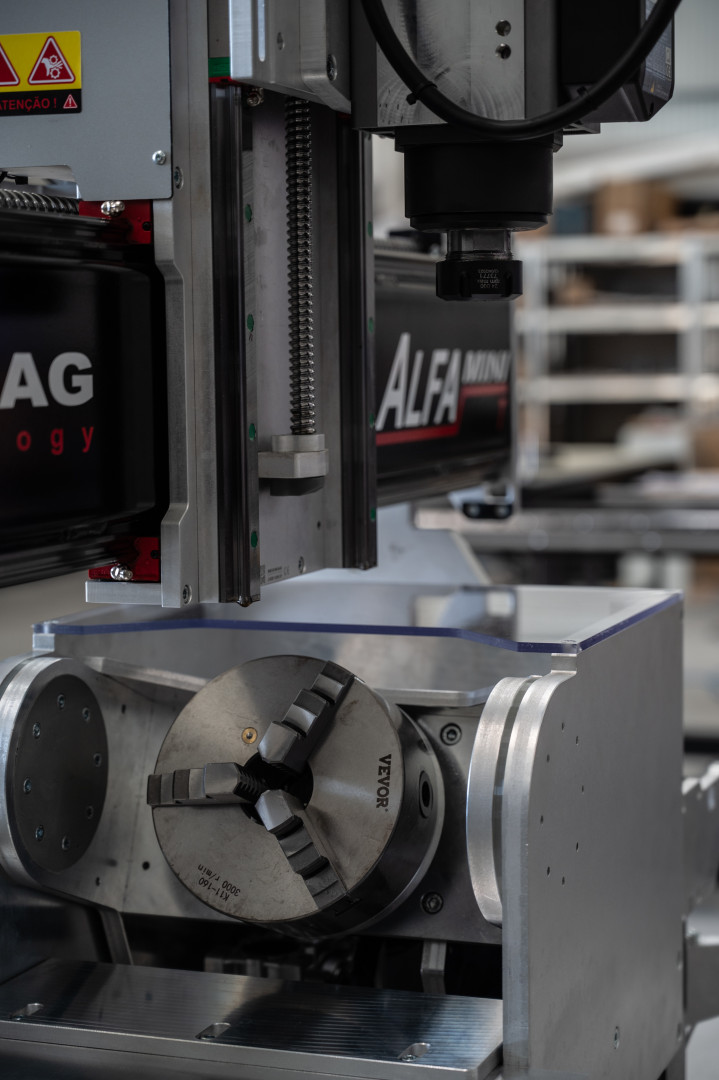

All Segmag CNC machines are built with a Cartesian system equipped with dual sensors, ensuring perfect squaring and high precision during CNC cutting operations. The dust extraction foot is motorized, automatically adjusting to the tool length. This system is available in both automatic tool change (ATC) and manual tool change (MTC) versions.

Whenever the tool changes, the dust skirt automatically adjusts to the new length. An automatic leveling function is also available, maintaining the skirt at the exact height of the material surface during machining. This ensures highly effective waste extraction. This smart dust extraction system is an innovation in the CNC machine market.

The CNC Alfa Pro can also be equipped with an automatic positioning stop system for material alignment. This optional feature allows customization in the number and placement of stops, tailored to each client’s specific production needs. Available in various standard sizes — from 600x600 mm up to 2100x1500 mm — the Alfa Pro can also be manufactured with custom dimensions, offering full flexibility for different space and production volume requirements.

The Z-axis has a travel of 300 mm, allowing cutting depths up to 150 mm, with the option to reach 200 mm. This capacity makes the Alfa Pro suitable for machining a wide range of materials, from wood and acrylics to composites and technical plastics. Designed with a strong focus on industrial performance, it effectively meets the needs of professionals seeking reliability and high output in every project.

Compatible with the latest operating systems, the CNC Alfa Pro features an extremely intuitive interface and integrates seamlessly into modern digital environments. It is fully compatible with leading CAD/CAM software such as Fusion 360, SolidWorks, VCarve, Aspire, and RhinoCAM, offering great versatility in CNC project preparation and execution. The Alfa Pro stands for flexibility, performance, and scalability — a model built to grow with your business.

Below is a list of available models with their respective dimensions. For other sizes, please contact us:

Alfa Pro 6060 – 700x700 mm

Alfa Pro 6010 – 700x1100 mm

Alfa Pro 1313 – 1400x1400 mm

Alfa Pro 1515 – 1600x1600 mm

Alfa Pro 2010 – 2100x1100 mm

Alfa Pro 2015 – 2100x1600 mm

Note: Length x Width

Have questions? Talk to us and find out everything about what you're interested in. We're here to help!