© 2026

All rights reserved segmag.pt •

Made with♥by

Criativatek

Talk to us!

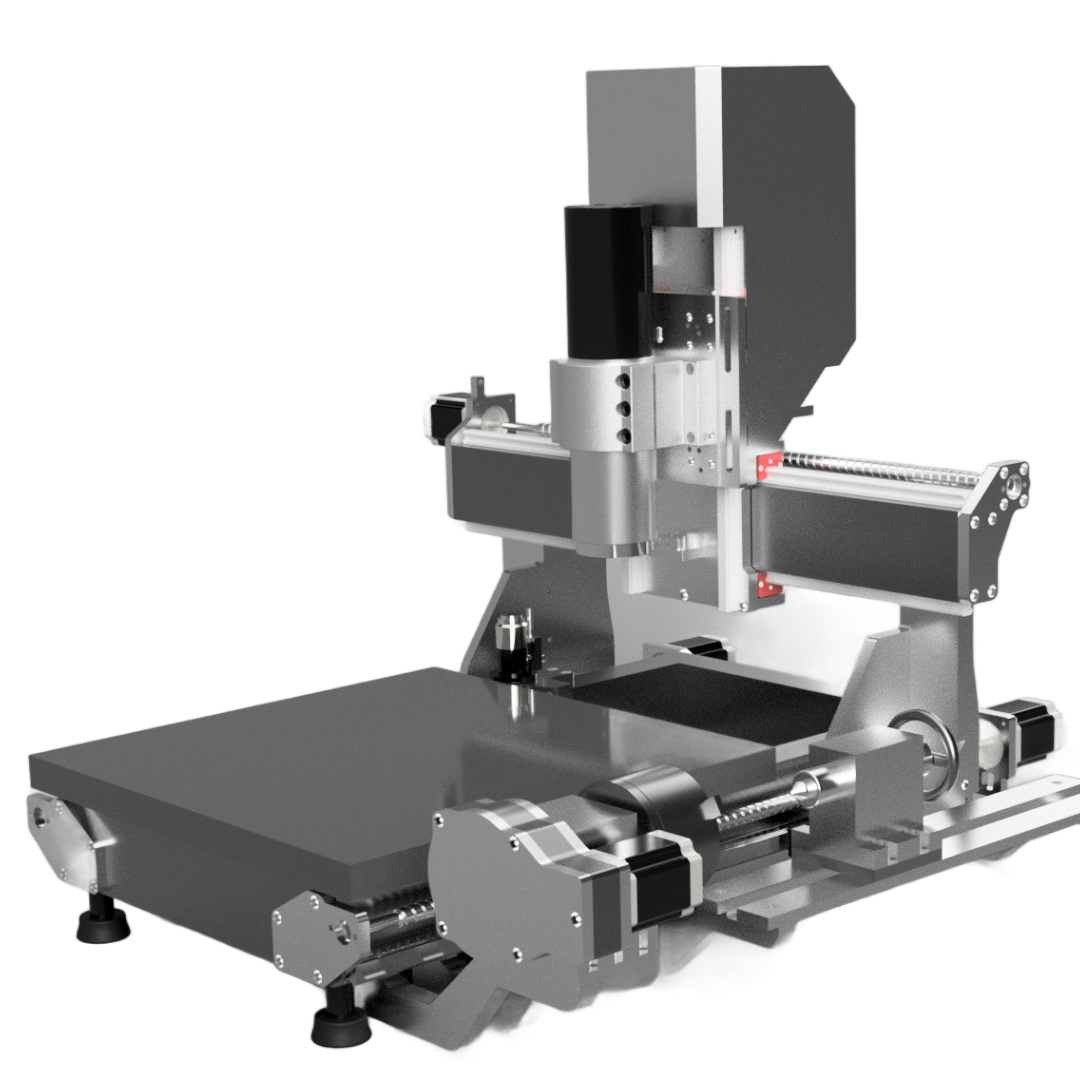

The CNC Beta Mini is a perfect CNC machine for compact spaces such as schools, laboratories, or offices. Capable of cutting materials up to 80mm thick, it is compatible with leading CAD/CAM software and modern operating systems. It delivers high-quality professional performance with a robust build and exceptional durability

Compact, versatile, and designed for technological education

Available in various standard sizes — from 450x450 mm up to 1000x600 mm — with the option for custom dimensions, the Beta Mini adapts to a wide range of space and production needs. The machine is supplied as a tabletop model (without stand), making it even more compact and easy to integrate.

The Z-axis with a 160 mm travel allows a cutting capacity of up to 80mm in thickness, suitable for a wide range of materials. The compact electrical cabinet, supplied separately, simplifies installation and ensures greater flexibility.

Designed with a strong focus on technological education, the Beta Mini provides a practical, safe, and accessible platform for students and educators to explore the principles of digital fabrication, electronics, and programming.

Compatible with modern operating systems, this machine features an extremely intuitive interface and easily integrates into current computing environments. It is fully compatible with major CAD/CAM software solutions — such as Fusion 360, SolidWorks, VCarve, Aspire, RhinoCAM, among others — offering great versatility in project setup and execution.

Optionally, it can be equipped with an automatic tool changer system or up to 5 axes, increasing efficiency, autonomy, and performance in production or educational environments. Additional accessories are also available.

The CNC Beta Mini is the ideal solution for those seeking precision, flexibility, and innovation in a compact and affordable format. It stands out for its low maintenance costs, thanks to a design that allows easy servicing and reduces downtime. Its robust construction ensures stability and accuracy even under intensive use. Built with high-quality materials, it offers exceptional durability over the years. It was specifically developed for compact spaces such as offices, prototyping areas, schools, technical laboratories, vocational training centers, and for CNC hobbyists seeking professional-grade performance.

Below is the list of available models with their respective working areas:

Beta Mini 4545 – 450x450 mm

Beta Mini 6045 – 600x450 mm

Beta Mini 4560 – 450x600 mm

Beta Mini 6060 – 600x600 mm

Beta Mini 6010 – 600x1000 mm

Beta Mini 10060 – 1000x600 mm

Note: Dimensions are listed as Length x Width

Have questions? Talk to us and find out everything about what you're interested in. We're here to help!