© 2026

All rights reserved segmag.pt •

Made with♥by

Criativatek

Talk to us!

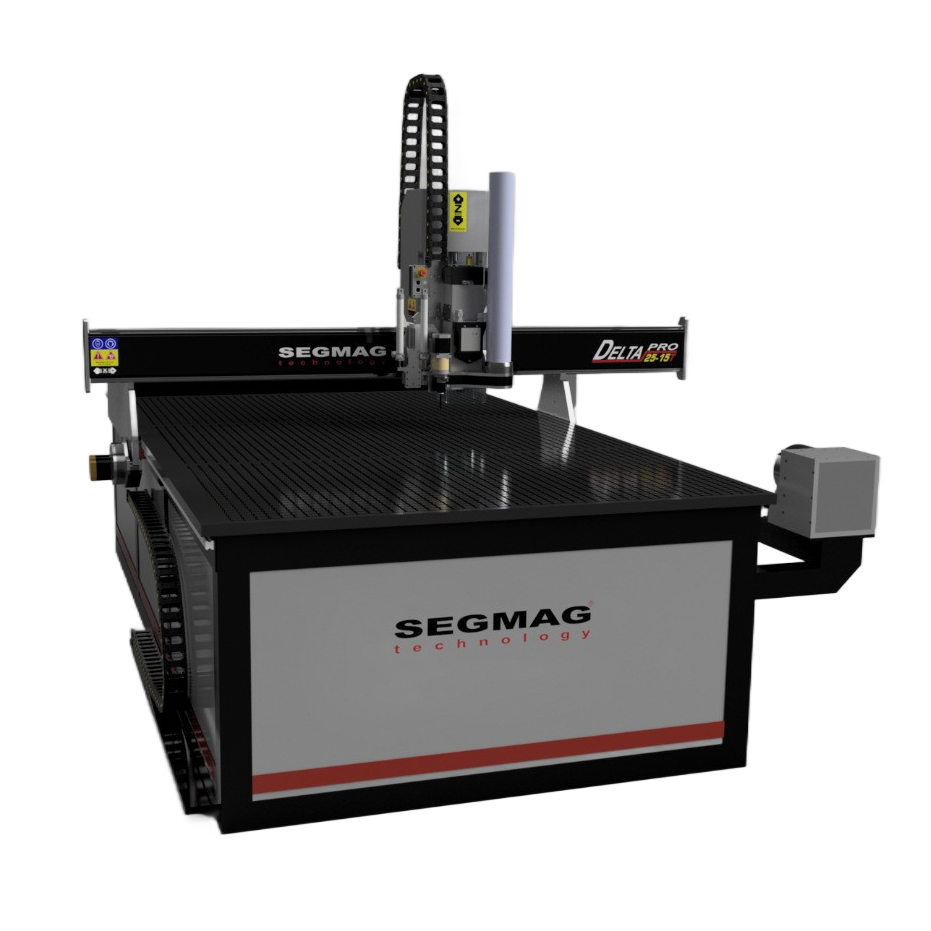

The CNC Delta Pro is a robust and precise machine, ideal for demanding industrial environments. Featuring an innovative dual pinion system, motorized extraction, and CAD/CAM compatibility, it delivers high performance, flexibility, and durability for complex CNC projects

Industrial efficiency, advanced technology, and optimized performance for daily productivity.

The CNC Delta Pro is the latest benchmark in performance and innovation within Segmag’s CNC machine range, raising standards of precision and reliability to new heights. Strengthened by the consolidated experience of the Beta Pro and Alfa Pro models, the Delta Pro was rigorously designed to offer maximum robustness, superior precision, and advanced features that meet the demands of the most challenging industrial environments. It is the unequivocal choice for those who require a high-quality CNC machine with large dimensions and flexibility to adapt to different working contexts. It combines cutting-edge technology with an optimized design to facilitate daily operation while staying true to Segmag’s core principles: ease of use, solid construction, durability, and low maintenance costs. Compared to previous models, the Delta Pro introduces decisive improvements such as a reinforced structure, larger motors, and higher travel speeds, among other technical optimizations that significantly boost productivity.

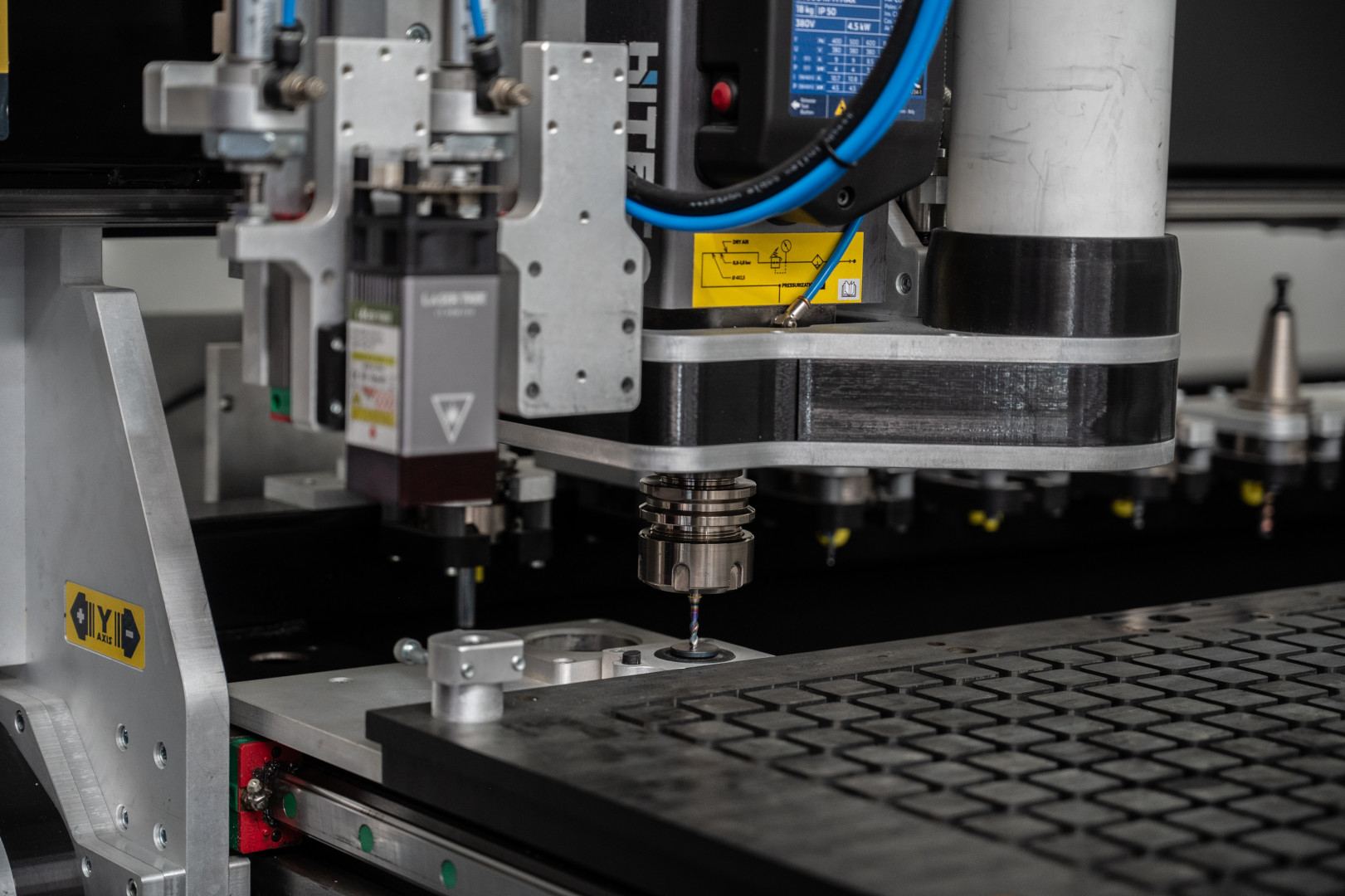

This professional model features mechanical movement via a helical gear rack and pinion system, an innovative design in the market thanks to its dual pinion configuration. This setup achieves exceptional performance in terms of speed and precision, with virtually zero backlash adjustment. Consequently, the Delta Pro guarantees the precision of a ball screw system but without the need for constant lubrication, enabling operation in any working environment.

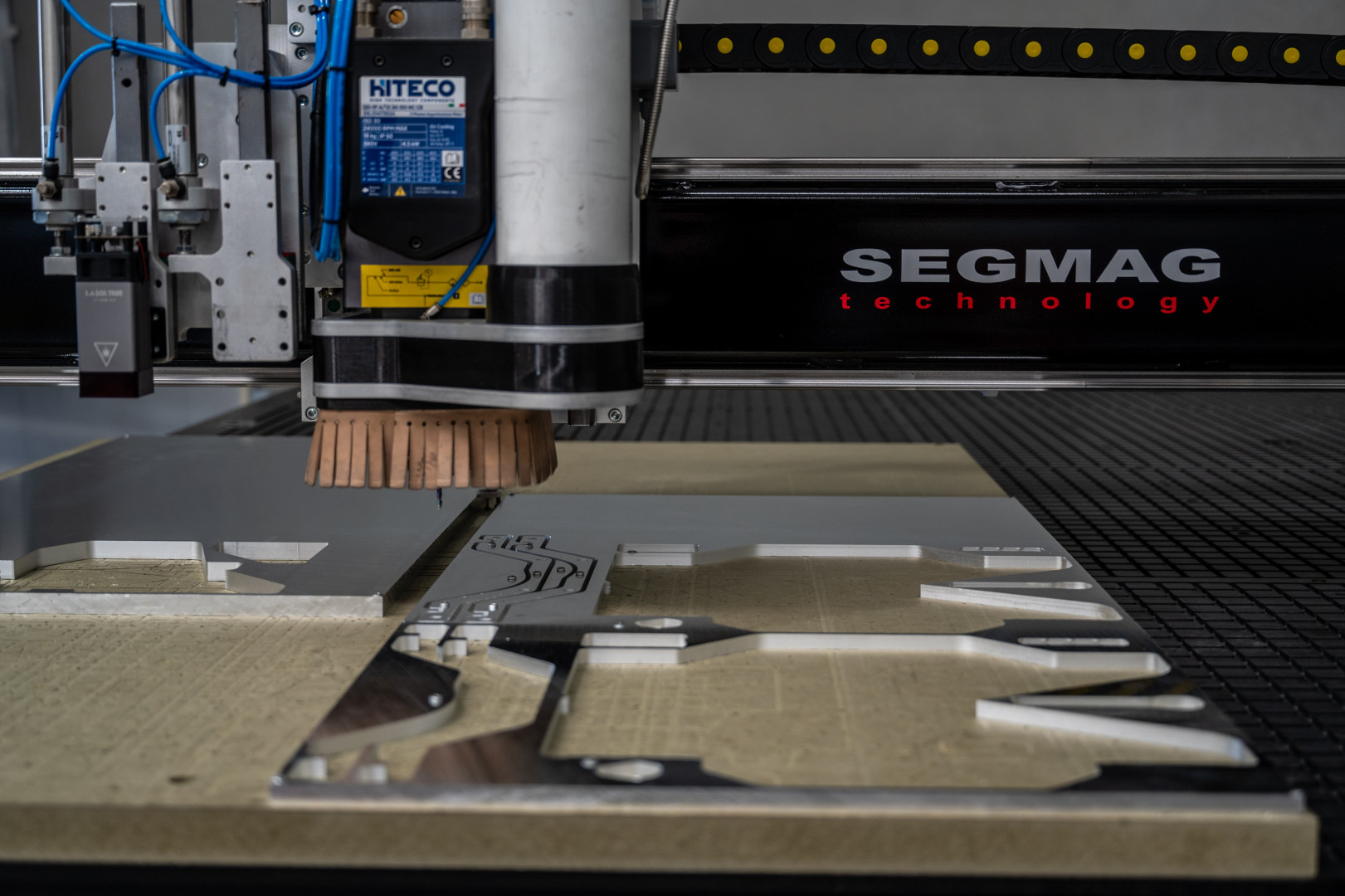

All Segmag CNC machines incorporate a Cartesian system with dual sensors, ensuring perfect squaring and high precision during CNC cutting operations. The extraction foot is motorized, automatically adjusting to the tool length, and is available both in versions with automatic tool change (ATC) and manual tool change (MTC). Whenever a tool change occurs, the extraction skirt automatically adapts to the new tool length. An automatic leveling function is also available, keeping the skirt at the exact height of the material surface during machining, ensuring effective residue extraction. This intelligent extraction system is a true innovation in the CNC machine market.

The CNC Delta Pro can also be equipped with an automatic stop system for material positioning, an optional feature allowing customization of the number of stops to suit the specific needs of each client or production process. Available in various standard sizes — from 2000x1000 mm up to 10000x3000 mm — the Delta Pro can also be manufactured with custom dimensions, offering total flexibility to meet different space and production volume requirements.

The Z-axis, with a travel of 300 mm, allows a cutting depth of up to 150 mm, with an optional extension to 200 mm. This capability makes the Delta Pro suitable for working with a wide variety of materials, from wood and acrylics to composite materials and technical plastics. Designed with a focus on industrial performance, it effectively meets the needs of professionals demanding reliability, output, and precision in every project.

Compatible with the latest operating systems, the CNC Delta Pro features an intuitive interface and integrates easily into modern IT environments. It is fully compatible with the main CAD/CAM software on the market, such as Fusion 360, SolidWorks, VCarve, Aspire, and RhinoCAM, offering high versatility in CNC project preparation and execution. The Delta Pro represents flexibility, performance, and growth potential, making it a solid investment designed to support your business expansion.

Models

Below is a list of some available models with their respective dimensions. For other sizes, please contact us:

Delta Pro 2010 – 2100x1100mm

Delta Pro 2015 – 2100x1600mm

Delta Pro 3015 – 3100x1600mm

Delta Pro 3020 – 3100x2100mm

Delta Pro 4020 – 4100x100mm

Delta Pro 6020 – 6100x2100mm

Delta Pro 10020 – 10100x2100mm

Note: Length x Width

Have questions? Talk to us and find out everything about what you're interested in. We're here to help!