© 2026

All rights reserved segmag.pt •

Made with♥by

Criativatek

Talk to us!

.jpg)

.jpg)

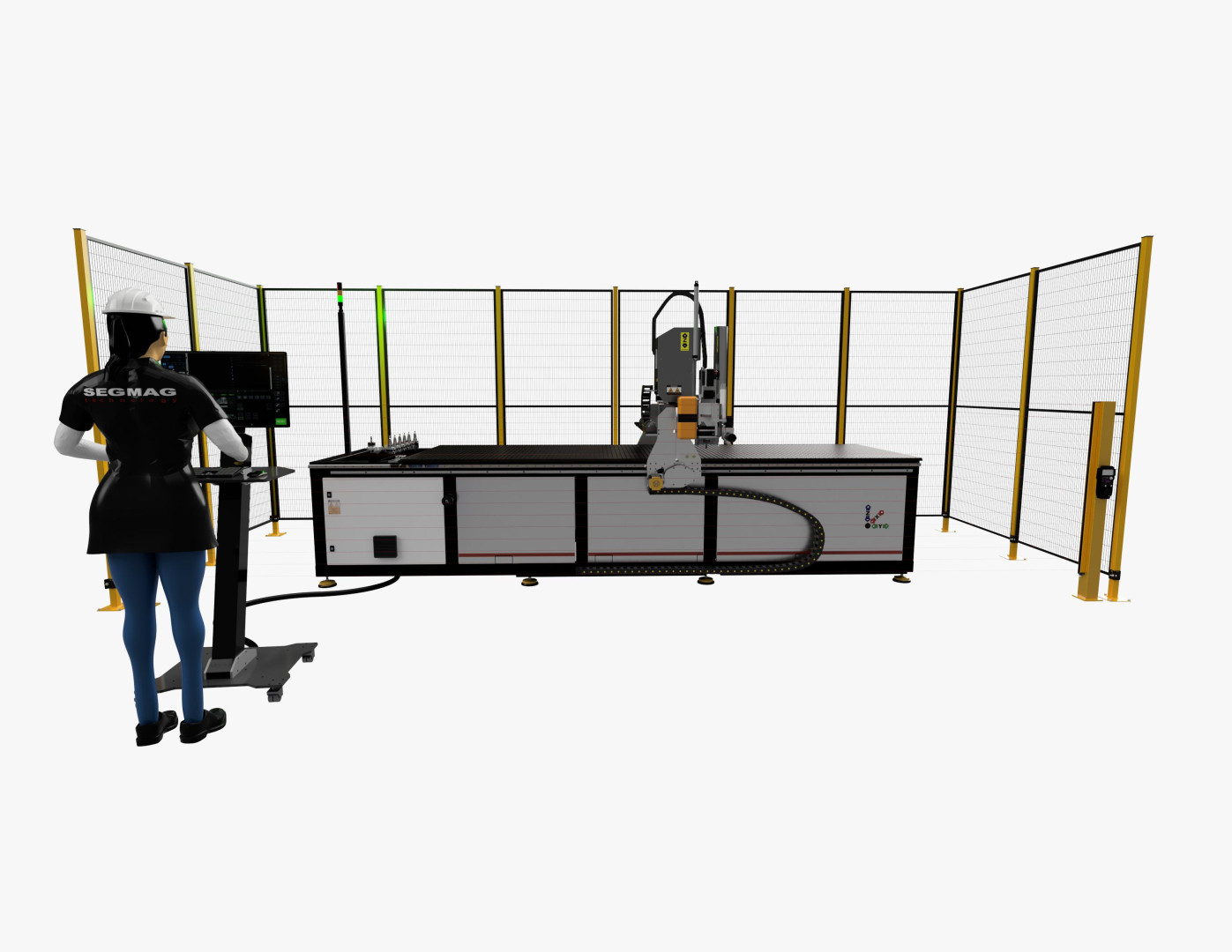

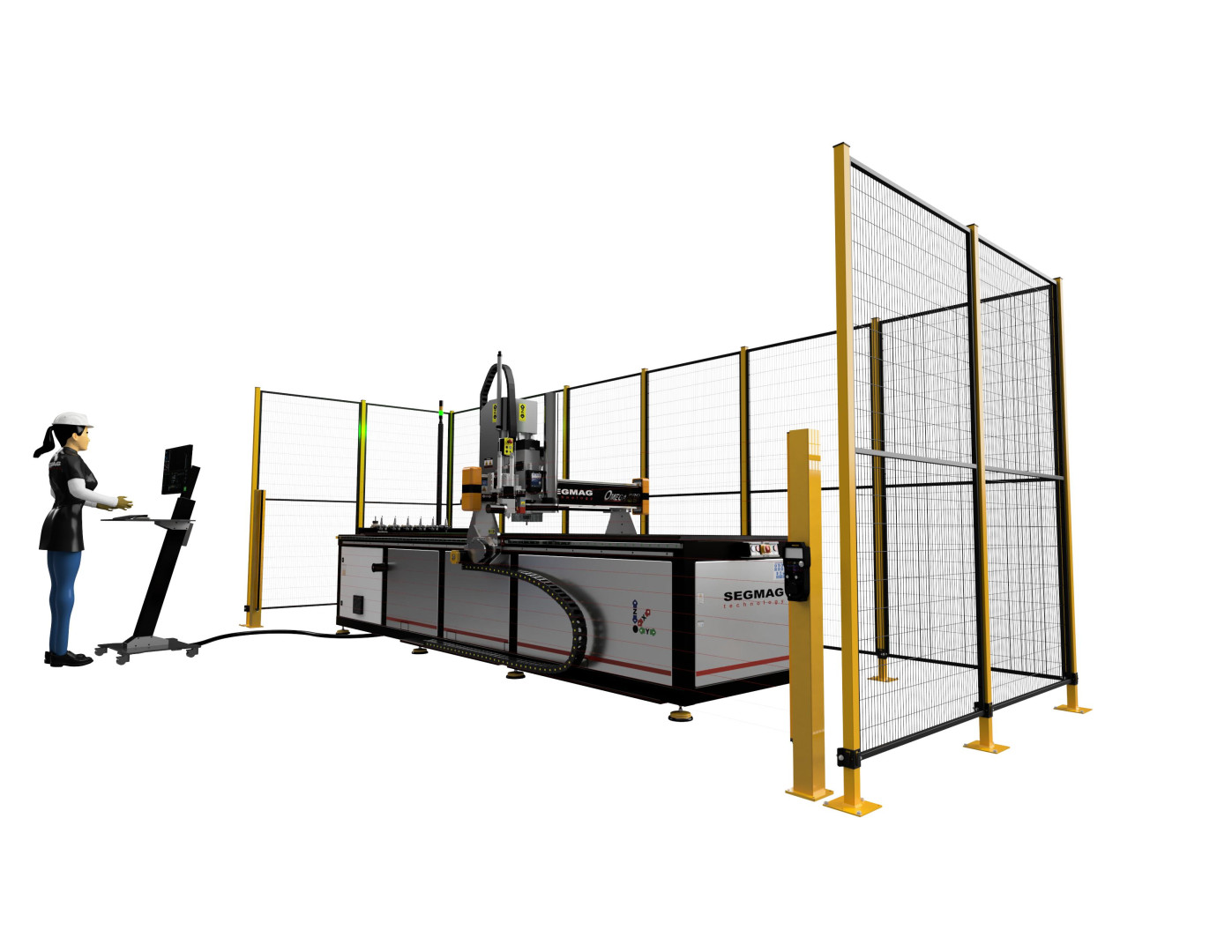

The CNC Omega Pro is a high-performance machine for intensive production. Robust, precise, and ready for automatic loading/unloading, it integrates milling, drilling, and custom aggregates. Ideal for demanding industrial environments that require reliability, speed, and full customization

General Specifications

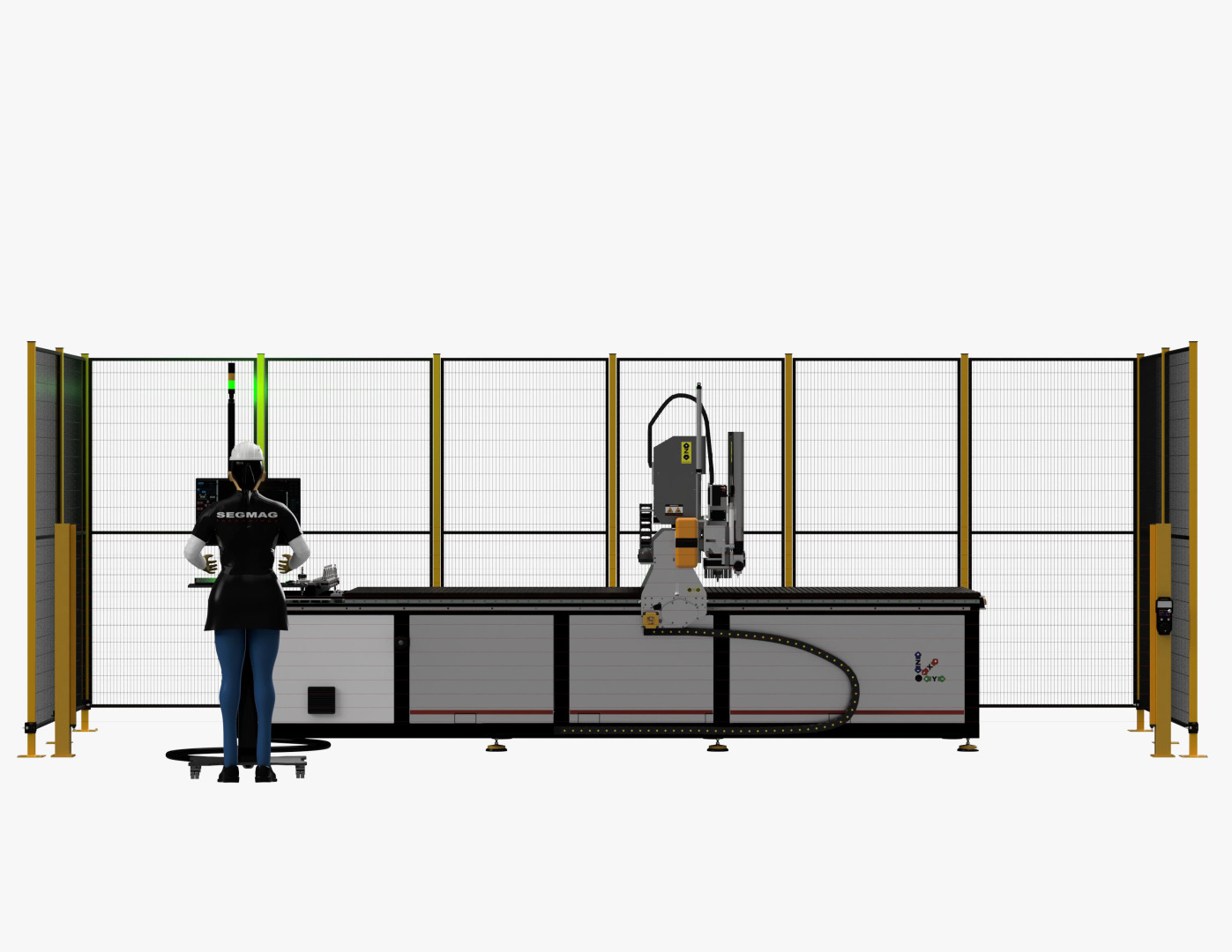

CNC Omega Pro: Extreme robustness, industrial precision, and total versatility for high-output production

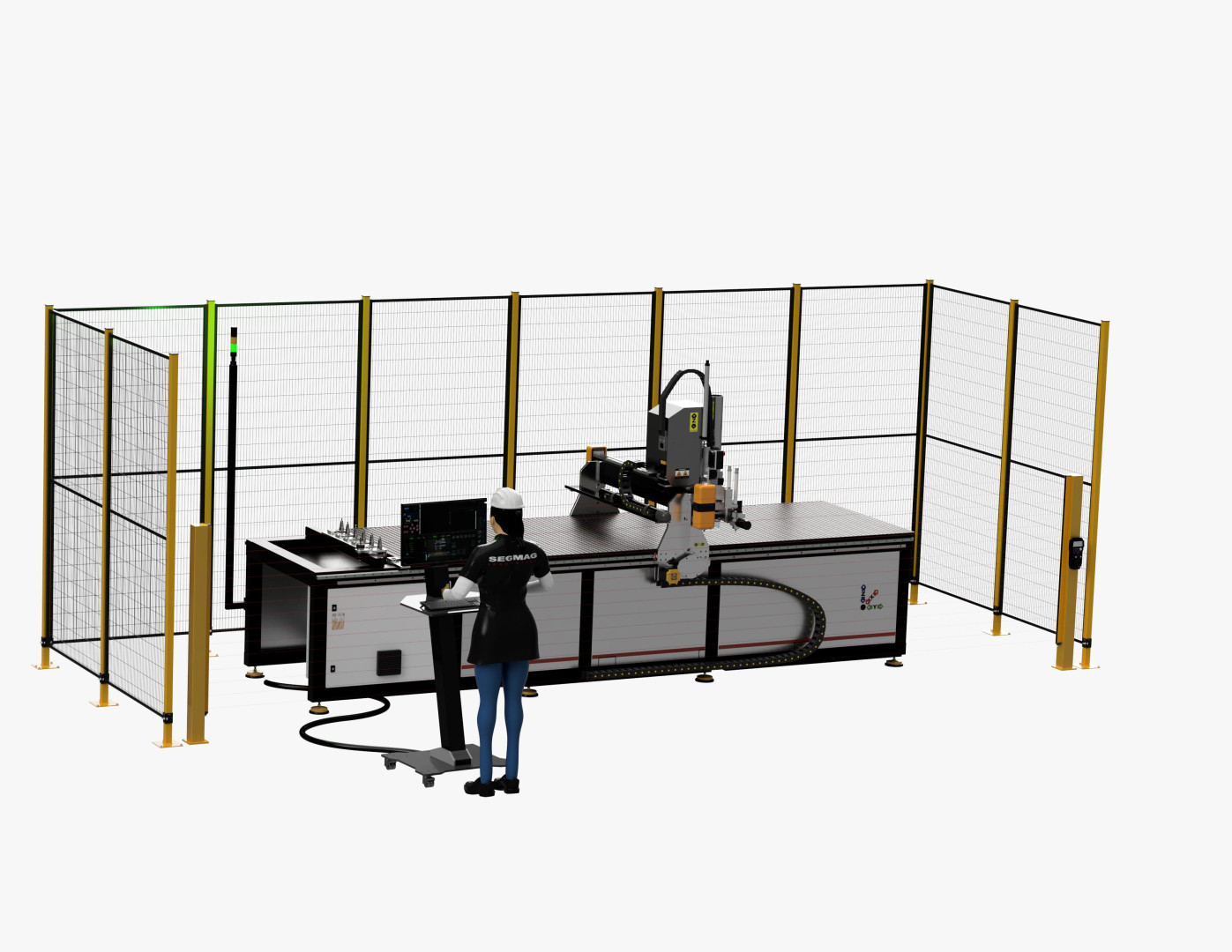

The CNC Omega Pro represents the pinnacle of Segmag engineering, designed to meet the highest production demands in the industrial sector. This model combines the most advanced mechanical construction, automation, and precision, raising the bar with an even more reinforced structure and a highly professional feature set. It is a CNC machine built for environments where reliability, structural rigidity, and continuous performance are absolutely essential.

The Omega Pro’s frame is built from high-strength welded steel, with an optimized geometry that eliminates twisting and ensures maximum rigidity. After welding, the frame undergoes a stress-relief treatment, ensuring dimensional stability even under heavy loads and continuous operation. This monobloc construction absorbs vibrations, improves cutting quality, and reduces component wear, resulting in a durable, precise machine with low maintenance requirements. Its robustness also allows for the integration of more complex accessories and optional equipment, such as vertical and horizontal drilling aggregates, pneumatic devices, and more.

With its standard features, the Omega Pro can be used for milling operations, surface processing, and vertical drilling, adapting to multiple industrial applications. Thanks to its high-speed operation, robust frame, and modular options, the machine is easily configurable to meet specific production needs. Its architecture also allows for the integration of automatic loading and unloading systems, optimizing production cycles in mass production environments where efficiency and speed are critical.

Mechanical movement is achieved through a helical rack and pinion system with dual pinions, allowing for high precision and fast positioning with virtually zero backlash. This technology outperforms conventional ball screw systems by offering the same accuracy with greater robustness and less need for continuous lubrication, making it ideal for dusty or thermally variable environments.

The motorized dust shoe automatically adjusts to the height of the tool in use, ensuring efficient and consistent chip extraction. This system is available in both ATC (Automatic Tool Change) and MTC (Manual Tool Change) versions. With the automatic leveling function, the dust skirt follows the material surface during machining, optimizing cleanliness in the work area.

The Omega Pro can also be equipped with automatic pneumatic positioning stops for material alignment, configurable in quantity and position according to the specific requirements of each production process. This automation speeds up setup times and reduces positioning errors.

Available in various standard sizes — from 2100x1500 mm to 10000x3000 mm — the Omega Pro can also be customized in dimensions and specifications to fit any production layout.

With a Z-axis travel of 300 mm, the machine allows cutting depths up to 150 mm, expandable to 200 mm as an option. It can work with a wide range of materials — from wood and MDF to technical plastics, composites, and aluminum — making it ideal for continuous, demanding production lines.

Fully compatible with the main CAD/CAM software on the market, such as Fusion 360, SolidWorks, VCarve, Aspire, and RhinoCAM, the Omega Pro integrates seamlessly into any digital workflow. The control interface is intuitive and ready for modern operating systems, ensuring a short learning curve and efficient operation from day one.

The CNC Omega Pro is Segmag’s ultimate solution for those who demand maximum performance, customization, and industrial-grade robustness in a single machine.

Models

Below is a list of available models with their respective dimensions. For other custom sizes, please contact us:

Omega Pro 2010 – 2100x1100 mm

Omega Pro 2015 – 2100x1600 mm

Omega Pro 3015 – 3100x1600 mm

Omega Pro 3020 – 3100x2100 mm

Omega Pro 4020 – 4100x2100 mm

Omega Pro 6020 – 6100x2100 mm

Omega Pro 10020 – 10100x2100 mm

Note: Length x Width

Have questions? Talk to us and find out everything about what you're interested in. We're here to help!