© 2026

All rights reserved segmag.pt •

Made with♥by

Criativatek

Talk to us!

.jpg)

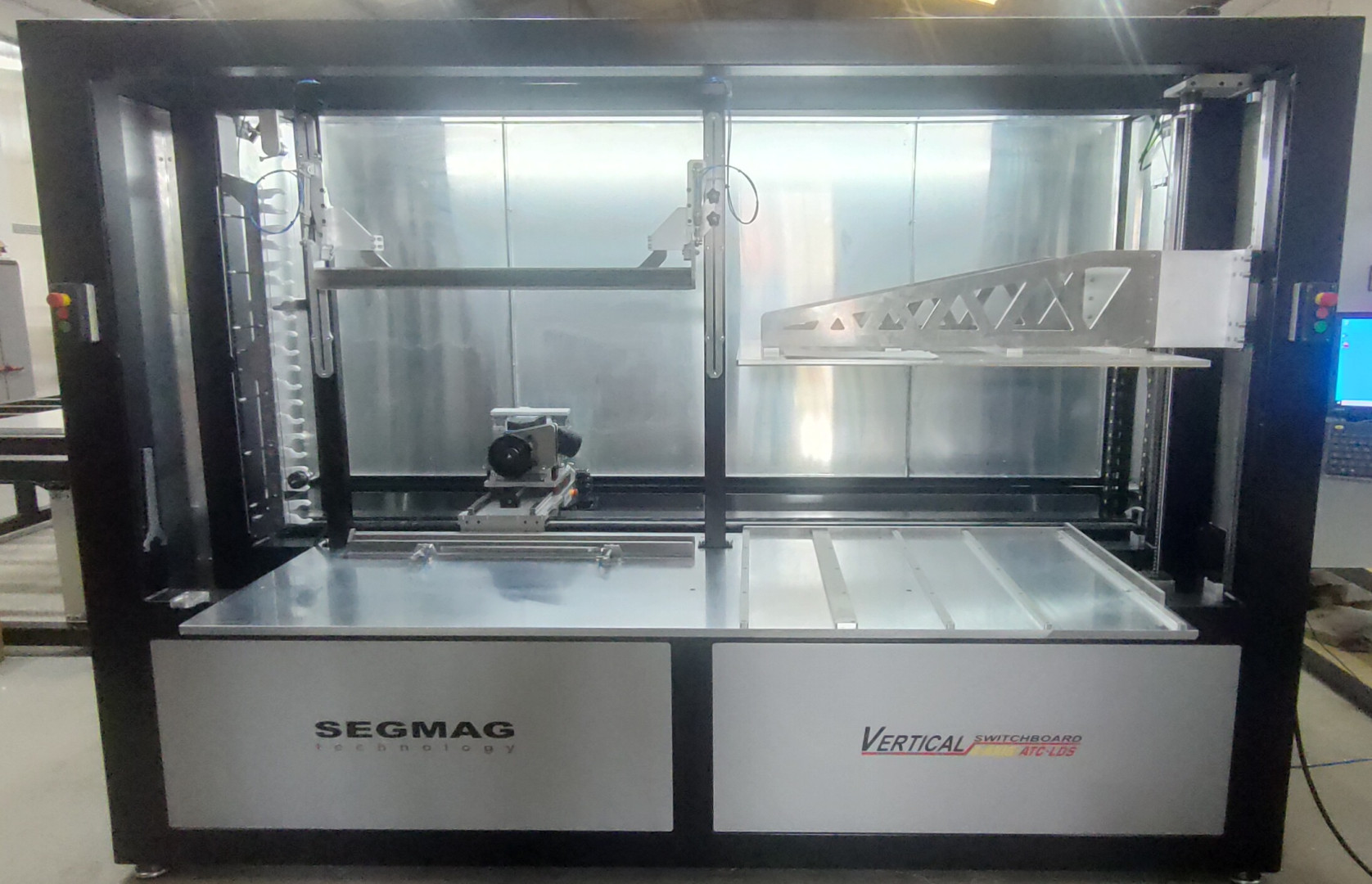

The CNC Sigma Pro stands out for its vertical milling and drilling capabilities, allowing the workpiece to be clamped in a vertical position for easier visual access to multiple faces. This innovation optimizes production space while enhancing precision and productivity, clearly setting it apart from the other models we offer

General Specifications

CNC Sigma Pro: High-Precision Vertical Milling, Industrial-Grade Structure, and Optimized Space for Intensive Production

The CNC Sigma Pro represents a breakthrough in vertical machining, establishing itself as the pinnacle of Segmag engineering. Designed to meet the most demanding requirements of modern industry, this machine combines a reinforced structure with advanced automation and control technology, ensuring precision, robustness, and high performance in vertical milling operations. Intended for demanding industrial environments where reliability and rigidity are critical, the Sigma Pro sets new standards in productivity by promoting efficiency and maximizing floor space.

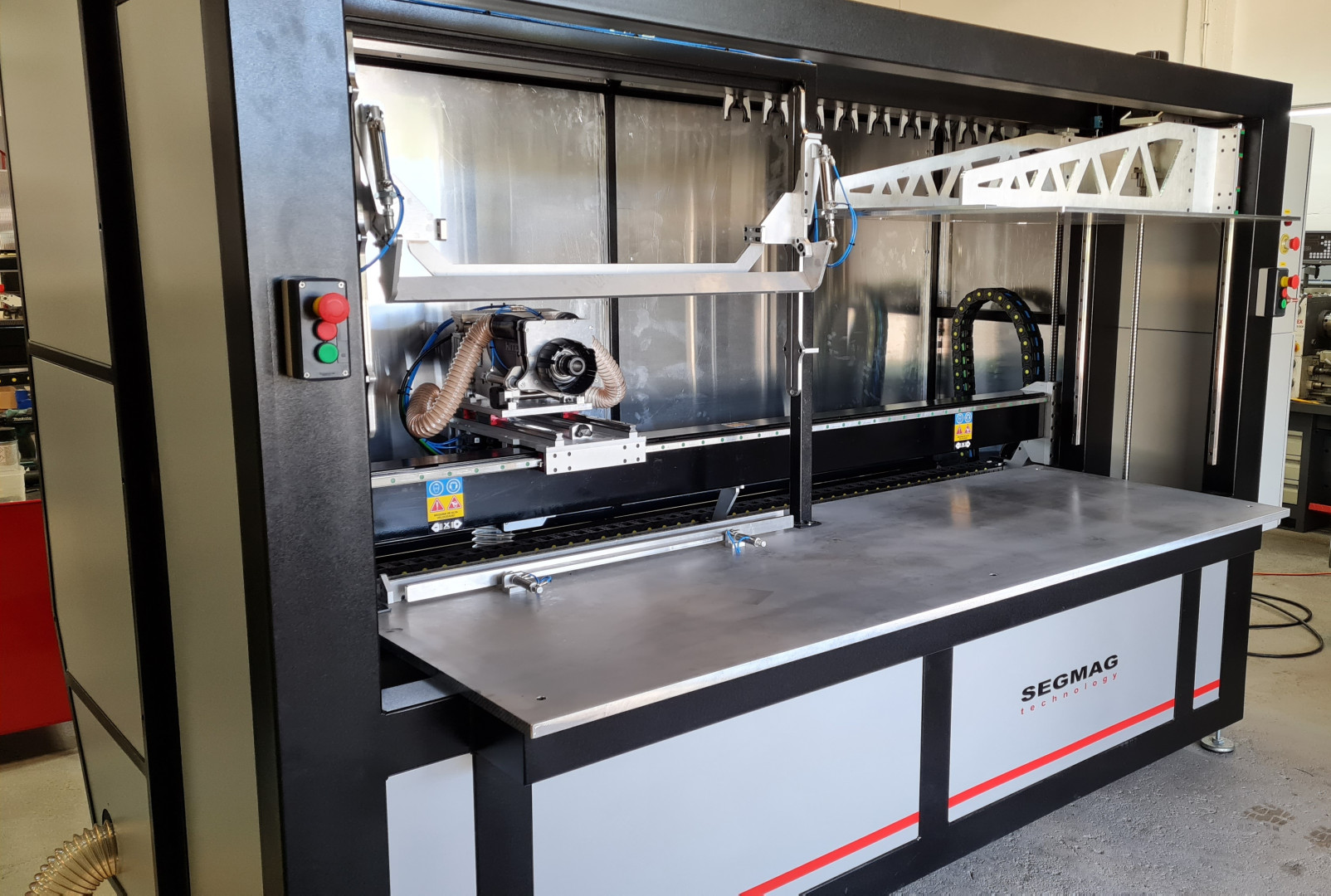

The Sigma Pro’s structure is built from high-strength welded steel with carefully optimized geometry to eliminate twisting and ensure maximum rigidity. This monobloc construction enhances vibration absorption, improves cut quality, and reduces component wear, resulting in long service life and minimal maintenance.

One of its most distinctive features is its vertical milling capability: parts are clamped and machined in a vertical position, optimizing available space and providing high-precision access to multiple faces. The system is designed to reduce setup times, including rapid part clamping, thereby accelerating the production cycle and minimizing downtime.

With its standard features, the Sigma Pro performs vertical milling and drilling, adapting to various industrial applications. Thanks to its high-speed operation, robust structure, and modular architecture, the machine can be easily configured for specific production needs.

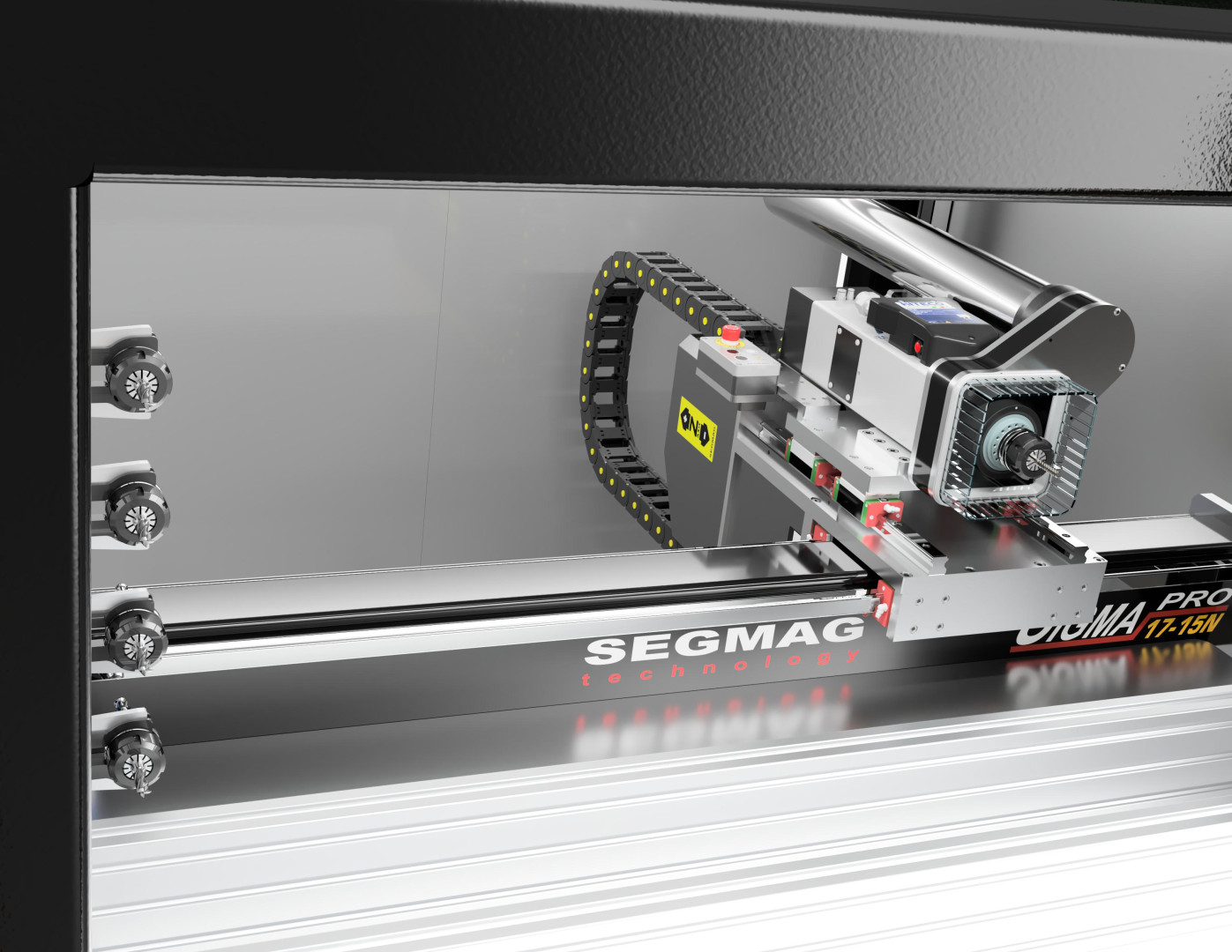

Mechanical movement is driven by a helical rack and pinion system with dual pinions, offering high precision, speed, and virtually zero backlash. This system outperforms traditional ball screw mechanisms, delivering the same accuracy with greater durability and less need for continuous lubrication—ideal for dusty environments, chips, or thermal variations.

The motorized dust extraction foot automatically adjusts to the height of the tool in use, ensuring effective and consistent waste removal. The auto-leveling skirt follows the workpiece surface, maintaining a clean working area. This system is available in both automatic tool change (ATC) and manual tool change (MTC) versions.

The Sigma Pro stands out for its versatility, with customizable dimensions and configurations to suit any workspace or production requirement. The Z-axis travel is also adjustable, allowing machining of a wide range of materials, including fiber-reinforced electrical panels.

Fully compatible with leading CAD/CAM software such as Fusion 360, SolidWorks, VCarve, Aspire, and RhinoCAM, the Sigma Pro integrates seamlessly into any digital workflow. Its control interface is intuitive and supports modern operating systems, ensuring a short learning curve and efficient operation from day one.

The CNC Sigma Pro is Segmag’s ultimate solution for those seeking high-performance vertical milling, industrial-grade robustness, and optimized production space.

Models

Please contact us for more information.

Have questions? Talk to us and find out everything about what you're interested in. We're here to help!